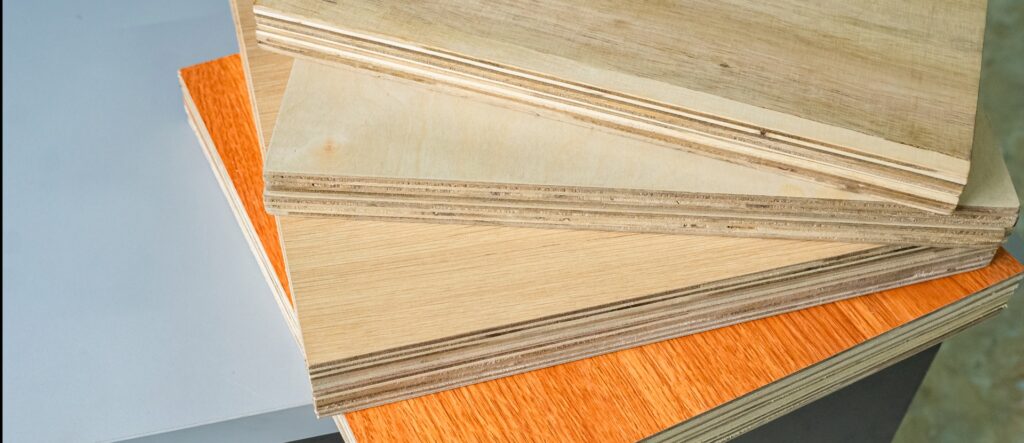

Plywood is a creation of the engineered wood industry, made from several layers of veneer arranged at right angles to each other, with the grain direction of each layer alternating. These layers are bonded together using Formaldehyde adhesive under the influence of heat and pressure. In the structure of plywood, the number of layers in a sheet is always odd (3, 5, 7, 9, etc.) to ensure that there is a core layer in the middle, creating identical grain patterns on both sides of the core. This arrangement helps the layers to resist warping, cracking, or splitting. As a result, the thin layers on both sides of the core are tightly held, preventing them from expanding or contracting freely. Due to the way the wood layers are arranged, plywood does not warp or shrink under normal conditions.

Plywood has high durability, good load-bearing capacity, can be bent, and is water-resistant. It can also be coated with veneer or melamine to enhance its aesthetic appeal. Due to these outstanding advantages, plywood is widely used in the construction of high-end interior and exterior furniture, wooden flooring, beams, formwork in construction, and more.

CONTACT INFORMATION

Headquarters in Hungary: 1142 Budapest, Tengerszem u. 25

Headquarters in Vietnam: 2A-4A Ton Duc Thang, Ben Nghe Ward, District 1, Ho Chi Minh City

Email: info.hungaryvietnamconnect@gmail.com

Contact: +84 904958400 / +84 90 279 22 62

Facebook: www.facebook.com/hungaryvietnamconnect